Okay, so today I wanted to try something totally different, something I’ve been curious about for a while – rotary engines. I mean, you hear about them, mostly in Mazda RX-7s, but I wanted to really get my hands dirty and see what makes them tick. Not just read about them, but actually, you know, build one. So I decided to build a rotary motorcycle engine. I found some basic designs, and, well, I just went for it.

Getting Started (and Getting Confused)

First thing I did was try to find some usable parts. I hit up some local junkyards, looking for anything that even remotely resembled engine components. I’m talking old lawnmower parts, bits of scrap metal, anything I could scavenge. It was kind of like a treasure hunt, except most of the “treasure” was rusty and covered in grease.

The Messy Middle

- Shaping the Rotor: This was a nightmare. I spent hours with a grinder and a file, trying to get that weird, rounded-triangle shape right. I ended up with a lot of metal dust and a rotor that, well, let’s just say it wasn’t exactly precision-engineered.

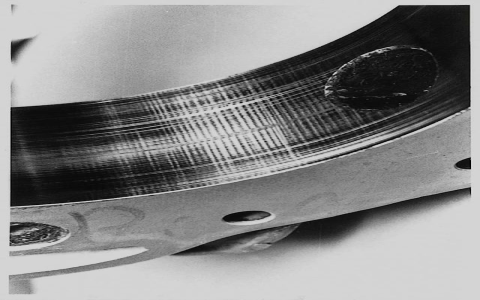

- Housing Troubles: Making the housing, the part the rotor spins inside, was even harder. I tried to bend some sheet metal, but it kept cracking. Eventually, I used pieces of the rotor housing from the junkyard.

- Seals, Seals, Seals: I learned real quick that rotary engines are all about the seals. Those little apex seals at the tips of the rotor? Super important. I fashioned mine out of some high-temperature rubber material. No idea if they’ll actually work, but they look the part.

- Intake, Exhaust, ignition system, and other necessary parts: I try my best to put them all together, and I use a lot of different parts from different engines to see if they could perfectly match. I spent nearly a whole day making the exhaust, which was a total headache.

Putting It All Together (and Hoping for the Best)

After days of tinkering, I had something that resembled a rotary engine. It was rough, it was ugly, but it was mine. I bolted it onto a spare motorcycle frame I had lying around. Honestly, the whole thing looked pretty ridiculous, but I was excited.

The Moment of Truth (or Disappointment?)

I hooked up a fuel line, said a little prayer, and cranked it. And…nothing. Not even a sputter. I checked everything, made some adjustments, and tried again. Still nothing. Turns out, my makeshift seals weren’t sealing, and the compression was basically zero. Major bummer.

So, yeah, my rotary motorcycle engine didn’t exactly fire up and roar down the street. But, you know what? I learned a ton. I learned how incredibly complex these engines are, and I gained a whole new respect for the engineers who actually make them work. Would I try it again? Maybe. But next time, I’m definitely getting better tools, and maybe some actual blueprints, not just going in my garage and starting from scratch.