Alright, let’s talk about messing around with R32 refrigerant. I’m no expert, but I like tinkering, so here’s how I went about getting my hands on some equipment and what I learned.

Finding the Gear

First, I needed to figure out where to even get R32-compatible stuff. Forget your regular hardware store, that’s for sure. I started by hitting up online forums dedicated to HVAC stuff – surprisingly helpful, those guys. I spent a solid week just lurking, reading old posts, and soaking up information.

Eventually, after a lot of looking around,I Found a couple of tools i want.

My First Attempt: The Setup

So, the tools arrived. Got everything unboxed, felt like a kid on Christmas. I’d read up on safety stuff (R32 is mildly flammable, you know, so no playing with fire), so I made sure my workspace was well-ventilated and I had a fire extinguisher handy – just in case. Paranoid? Maybe. But better safe than sorry, right?

Setting up the manifold gauge set was… interesting. I spent a good hour just staring at the hoses and the different colored valves, trying to remember which one was for what. Finally, I connected everything, double-checked all the fittings (don’t want any leaks!), and took a deep breath.

The Experiment (and a Few Oops Moments)

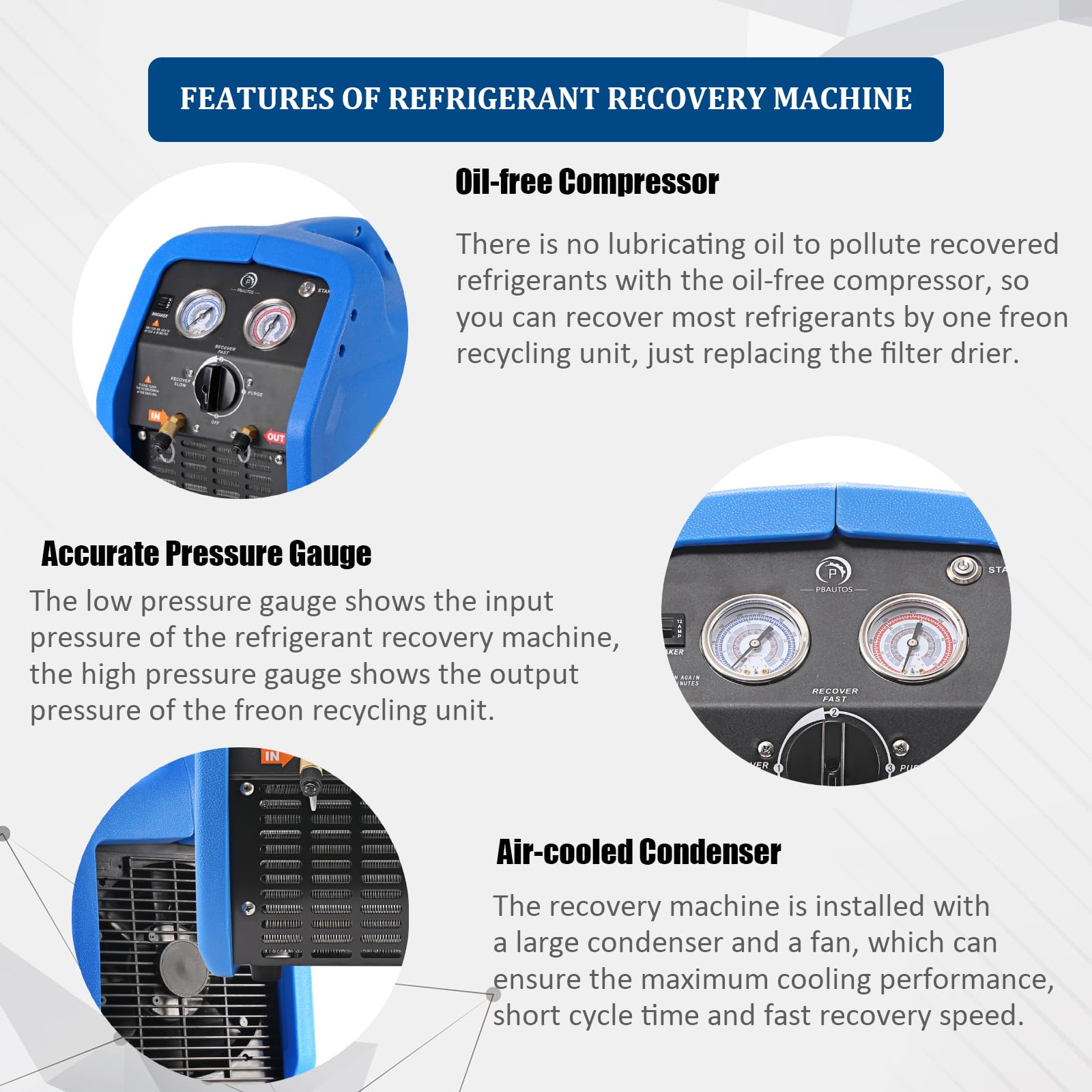

I connected the recovery machine to the old AC unit. Turned it on, and… nothing. Okay, panic mode for a second. Then I realized I hadn’t plugged the recovery machine into the wall. Facepalm moment number one. Plugged it in, flipped the switch, and it started humming. Progress!

The gauges started showing pressure readings. I watched them, slowly starting to understand what was happening. After a while, I decided to try adding a little bit of R32 to the system, just to see how it responded. I opened the valve on the refrigerant cylinder very slowly, listening for any weird noises.

Everything seemed fine, and I noticed a slight change in the pressure readings. Success! I let it run for a bit, monitoring everything closely. Eventually, I decided to shut it down, feeling pretty good about myself.

I learned the hard way that patience is key. And also that YouTube tutorials are your best friend when you’re completely clueless. I’m not saying I’m a pro now, but I definitely feel more comfortable messing around with this stuff. Still got a lot to learn, though. It’s a journey, not a race, right?