Alright, so let me walk you through this ceramic engine parts thing I finally got around to testing. Always heard whispers about ceramics making engines better, but talk is cheap. Needed to see for myself.

Starting Point: Pure Curiosity

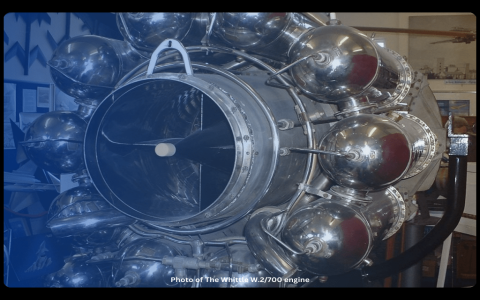

First off, just grabbed a small, cheap lawnmower engine. Figured it wouldn’t matter much if I wrecked it trying something dumb. Popped it off the mower, dumped it on the workbench – this thing was grimy. Started by tearing it down completely. Pistons, cylinder head, valves… all the usual metal bits laid out.

Getting the Ceramics Bits

Finding actual ceramic parts was harder than I thought! Not exactly something you pop down to the auto store for. Ended up ordering a tiny ceramic piston crown and a little plate thing, like a thermal barrier coating sample someone made, plus some ceramic valve seats meant for some niche racing application. Definitely not cheap, felt kinda crazy spending it on a grimy lawnmower block.

Here’s what I swapped in:

- The Piston Top: Took off the metal piston top and slapped on this weird, almost coffee-cup looking ceramic crown. Weirdly light compared to the metal one.

- Valve Seats: Yanked the old metal rings out and carefully pushed these dark, rock-hard ceramic seats into the cylinder head.

- That Heat Shield Plate: Put this flimsy-feeling thin ceramic tile on the inside of the exhaust port side of the cylinder head, facing the piston.

Putting it all back together felt slightly sketchy. You know that feeling when you’re using parts that aren’t quite standard? Yeah, like that.

Firing It Up (Literally)

Hooked the engine back up to fuel and a starter. First crank? Nothing. Just coughing. Messed with the spark plug timing a bit – got it firing finally. Holy smokes, the sound difference! It ran way smoother than before, almost… quieter, but sharper? Hard to describe. Revved it up, and damn, it responded quicker than I remembered.

Testing the Heat Theory

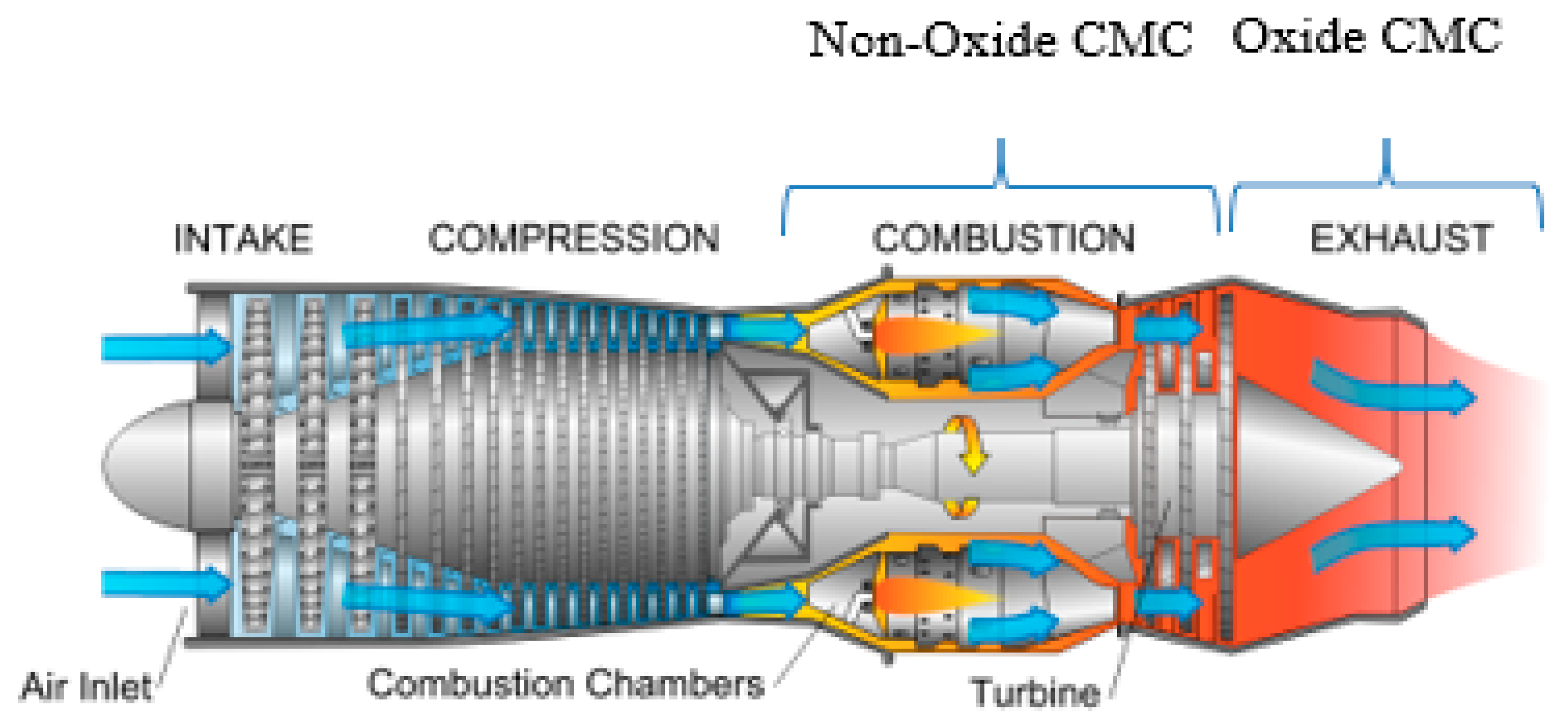

This was the big one for me. Everyone always yaps about ceramics dealing with heat better. So I let it run hard for a good while. Normally, after running hard, touching the cylinder head gets you a nasty surprise – real hot, real fast.

With the ceramics? Grabbed an infrared thermometer. Pointed it at the metal parts like the crankcase – scorching hot, like before. Pointed it at the cylinder head itself (especially near the exhaust), also hot. But when I checked the reading from where that little ceramic heat shield plate was inside? Way cooler. Like, surprisingly different. Didn’t burn my fingers touching the outside area above it as easily as before the swap. That kinda blew my mind – proof those ceramics were actually blocking some serious heat from escaping where you don’t want it.

So… Why Bother? Why Now?

After messing with it, tinkering, feeling the difference? It started clicking.

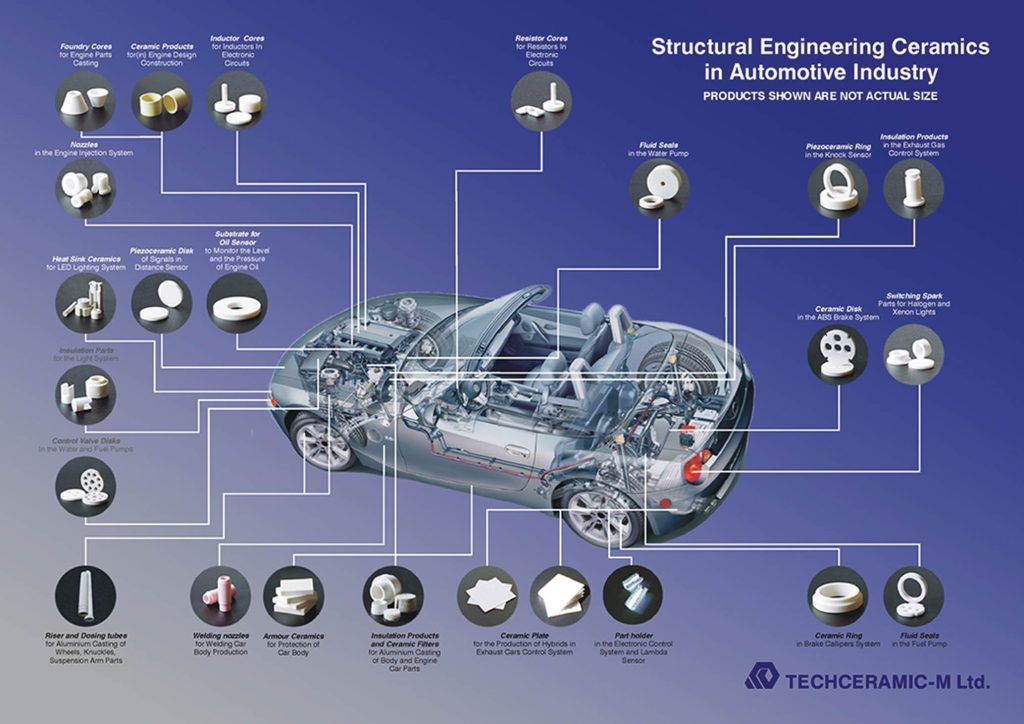

- Running Leaner & Hotter: They want engines to run hotter to burn cleaner and more efficient? This ceramic stuff lets them do that without literally melting the engine internals. My little heat test proved that.

- Less Wasted Energy: Feeling how much cooler some engine spots stayed means less energy is literally just heating up metal uselessly. More heat is actually pushing the piston, hopefully meaning less gas burnt for the same oomph.

- Tougher Where it Counts: Them valve seats? Smashed hot fuel/air hundreds of times without a scratch. That wear-resistance thing is real – less grindy bits wearing away over time.

Bottom line? Yeah, they aren’t building entire engines outta coffee mugs yet. But sticking these super hard, heat-hating ceramic chunks into the absolute hottest, harshest spots? It ain’t magic, it’s just smart engineering. Lets engines take way more punishment and potentially give you more miles per gallon without falling apart. That’s why car companies are sneaking this stuff into high-end stuff now. Messing with it myself? Definitely see the fuss.