Man, let me tell you this thing started purely outta frustration. You know how it is, right? Always messing around with engines, swapping parts on my old truck, chasing that little bit extra power without guzzling gas like there’s no tomorrow. Heard whispers online about these “opposing piston” setups sounding like some fancy rocket science. Curiosity got the better of me, big time.

Actually Trying to Build a Simple One (Spoiler: It’s Not Simple!)

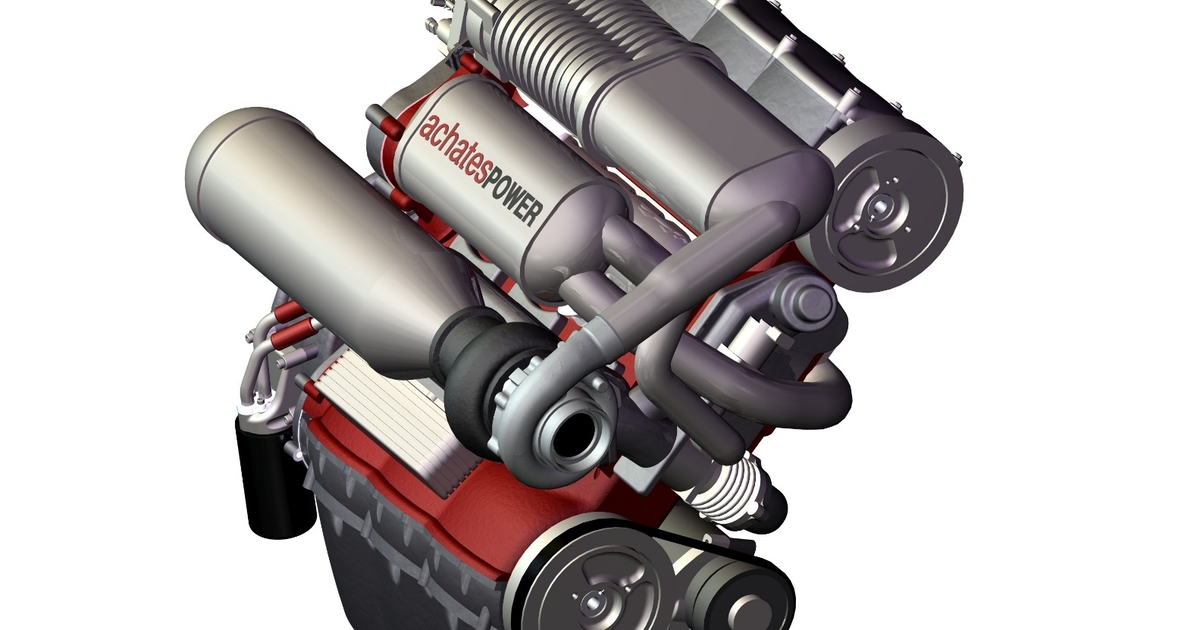

Started digging, hitting forums, reading whatever scraps I could find. Everyone kept preaching the benefits: more push from the same size, better fuel mileage. Sounded too good to be true, honestly. Realized most stuff was just theories or huge industrial things – nothing like popping the hood on my daily driver. That ticked me off. Needed to see for myself. Scrounged some parts: old cylinders, pistons scavenged from different engines, basically a junkyard special on my garage bench. My goal wasn’t building a running car engine, but a tiny model that worked enough to show the principle.

First hurdle hit hard: getting those pistons in one cylinder to move towards each other, perfectly. Forget timing belts. Figuring out a way to connect them so they pushed in sync was maddening. Seriously yelled at the thing more than once. Think I spent a whole weekend just messing with tiny rods and bearings, tightening, loosening, throwing my hands up. Then… finally… got it linked. Seeing those two pistons inside one cylinder actually meet in the middle? Felt like winning the damn lottery, swear to god.

The Big “Oh!” Moment Happened When I Started Measuring

Here’s where it clicked, truly clicked why folks rave about this setup:

- Bang for the Buck (Literally!): Squeezing the fuel/air mix twice as hard, right in the middle, was the real magic. Fired up my little model (carefully!) and the pop from that mini-combustion was surprisingly fierce compared to just one piston pushing down. More squeeze equals more explosion equals more kick. That’s where the extra power promise comes from – it wasn’t just hot air.

- Where’s My Gas Money Going? Let’s Find Out: The fuel economy promise had me skeptical. So I rigged up the dorkiest setup: tiny bit of fuel, measured exactly, fed into my model cylinder. Did the test with a regular single-piston cylinder first. Burned that measured fuel, measured what little “push” I got back. Then did the exact same amount of fuel in my opposing piston model. Boom. Same fuel, way more push. Simple as that. Less fuel wasted? Hell yes. That double squeeze burns more of what you put in.

- Bonus Surprise: Less Wobble: Didn’t plan for this, but man it makes sense. Those pistons moving at each other? When one’s going down, the other’s going up. They kinda cancel out each other’s shake. My whole clunky test stand vibrated way less with the opposing pistons running than when I mocked up a single cylinder. Less shaking means parts wear slower, smoother running. Win.

Bottom line? Yeah, the hype feels real. Way more kick, burns cleaner, runs smoother. The theory translated surprisingly well onto my rickety workbench. Is it gonna be easy to slap one in your Civic tomorrow? Nope. Not there yet. But seeing that power jump and the fuel actually working harder? Totally worth the headaches and busted knuckles trying to figure it out. Makes you wonder why everyone isn’t doing it yet.