Alright, folks, let’s dive into my latest project: messing with an HD Knucklehead motor. I’ve always been fascinated by these old engines, the history, the sound, the pure mechanical beauty of them. So, I finally took the plunge and got my hands on one. It wasn’t pretty, mind you. This thing was rough.

Getting Started

First thing I did was tear it down completely. Every nut, every bolt, every greasy, grimy piece came apart. I laid everything out on my workbench, which looked like a bomb had hit a hardware store. It was overwhelming, to be honest, but I’ve learned that the best way to tackle a big job is one piece at a time.

Cleaning and Inspecting

Next up: cleaning. Oh boy, the cleaning. I spent days, I’m not kidding, days, scrubbing parts. Degreaser, wire brushes, toothbrushes (don’t tell my wife), you name it, I used it. I wanted every single piece to be spotless. This wasn’t just about making it look good; it was about seeing what I was really working with.

Once everything was clean, I could start inspecting. I checked for cracks, wear, anything that looked suspicious. The cylinders were scored, the pistons were shot, and some of the bearings looked like they’d been through a war. No surprises there, really, considering the age of this thing.

- Cylinders: Definitely needed honing, maybe even boring out.

- Pistons: Toast. Needed new ones, oversized probably.

- Bearings: Replaced ’em all. No point in risking it.

- Heads: Surprisingly, they weren’t in terrible shape. Just needed a good valve job.

Sourcing Parts

Finding parts for a Knucklehead isn’t exactly like popping down to your local auto parts store. I spent a lot of time on the phone, scouring the internet, and talking to old-timers who know these engines inside and out. It’s a hunt, but that’s part of the fun, right?

Putting It Back Together

Reassembly was slow and deliberate.I used assembly lub,make sure all is well, I took my time, double-checking everything, making sure every bolt was torqued to spec. This isn’t a job you want to rush. One wrong move and you could be starting all over again,I have learned it from my experience.

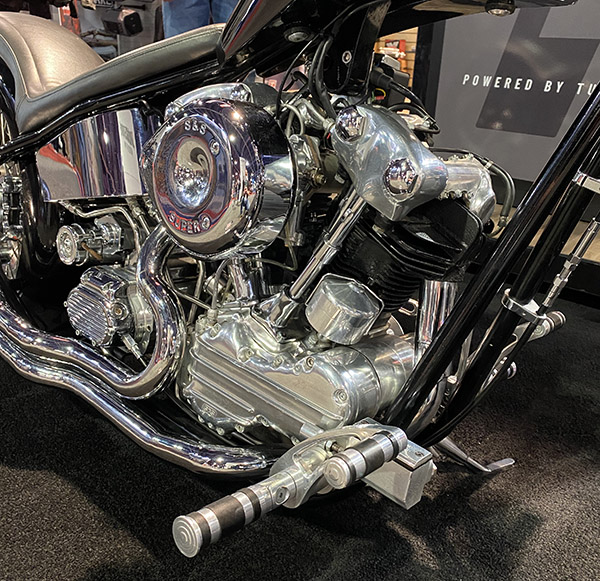

Finally got the short block assembled. It was a beautiful sight, all clean and shiny, with new pistons and bearings. Then came the heads, the pushrods, the timing gears… slowly but surely, it started to look like a motor again.

The Moment of Truth

With the engine back in the frame (that’s a whole other story), it was time for the moment of truth. I primed the oil pump, gave it a few kicks, and… nothing. A few more kicks, still nothing. My heart sank a little. Then, I remembered I hadn’t adjusted the timing quite right. A quick tweak, another kick, and… BOOM. It fired up! That Knucklehead roar, there’s nothing like it. It was rough, it was loud, it was perfect.

Still Work to Do

Of course, there’s still plenty to do. Fine-tuning the carb, adjusting the timing, getting the whole bike dialed in. But the hard part is done. I brought a piece of history back to life, and that’s a pretty damn good feeling.

It’s a never-ending project, really. But that’s the beauty of these old machines. They’re always teaching you something, always challenging you. And when you finally get them running right, it’s all worth it.