Alright, let’s talk about fiddling with active suspension. It wasn’t exactly on a brand new car, mind you. This started with an older project vehicle I picked up, ride quality was… well, let’s just say you felt every single pebble on the road. I’d heard about active systems and thought, how hard could it really be to make things a bit smoother, maybe even adaptable?

Getting Hands Dirty

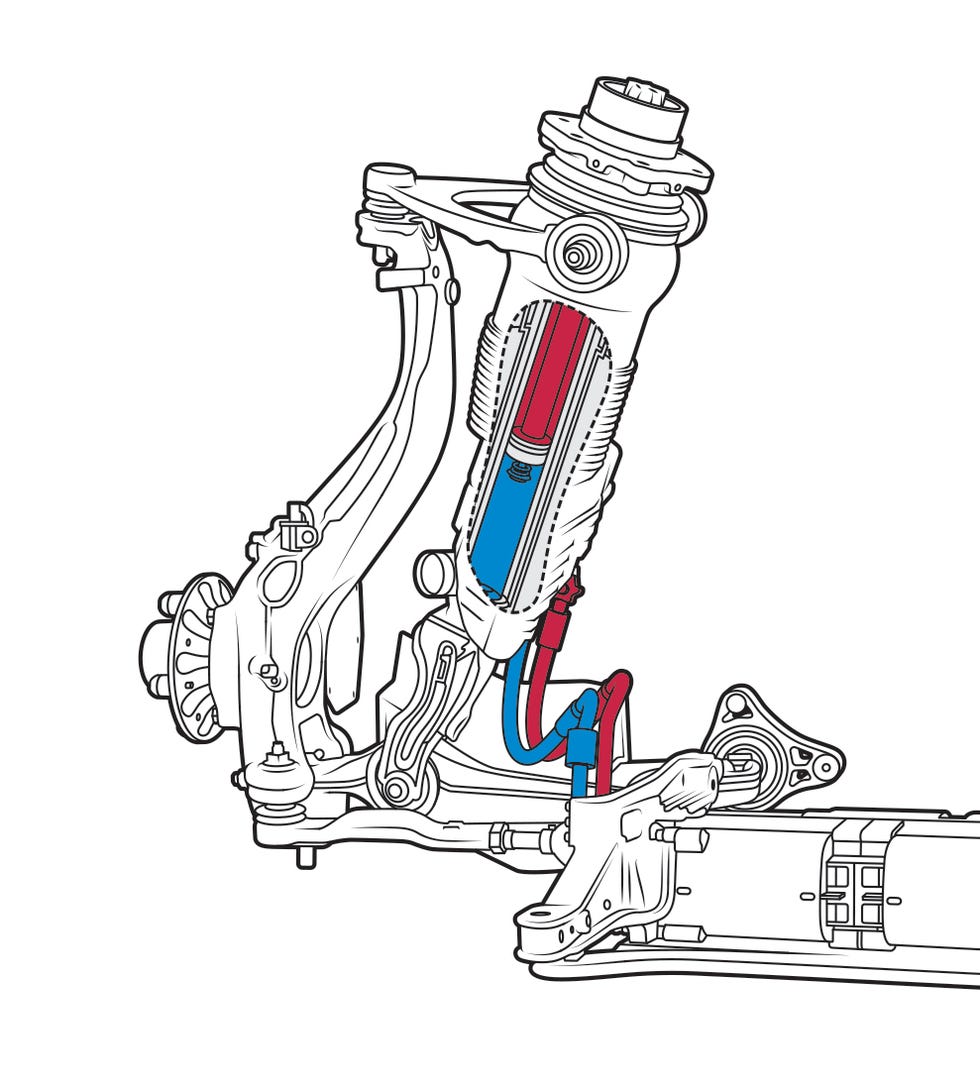

First off, I spent a good chunk of time just digging around, trying to understand the core idea. Forget the fancy marketing terms. At its heart, you’ve got sensors reading the road and the car’s movement, a brain box figuring out what to do, and then actuators – usually special shocks or hydraulic/air components – actually doing the work. Sounded simple enough on paper.

So, I started sourcing some parts. Not a full factory system, that would cost a fortune and be a nightmare to integrate. I was looking at more of a DIY / adaptable approach. Got some accelerometers, some ride height sensors, a programmable control unit, and a set of adjustable dampers that could react to electronic signals. The plan was to hook these up and try to program some basic logic: soften things up on smooth roads, stiffen them in corners.

The Reality Check

This is where things got messy. Mounting the sensors was the first hurdle. They need to be in exactly the right spots, stable, and protected. Took ages just getting the brackets fabricated and positioned correctly. Then came the wiring. Oh boy, the wiring. Running cables neatly, making sure connections were solid and waterproofed… it felt like I was building a telephone exchange under the car.

- Sensor placement: fiddly and crucial.

- Wiring: endless and needed to be robust.

- Control unit integration: more complex than expected.

Getting the control unit to talk to everything was the next big challenge. It wasn’t plug-and-play. I had to figure out the signal types, voltages, and write code to interpret the sensor data and send the right commands to the dampers. Debugging that code, with the car sitting on jack stands, wheels off, wires everywhere… let’s just say my patience was tested. Many, many times.

You quickly realize it’s not just about making shocks firmer or softer. It’s about the timing. The system needs to react instantly, predict even. A fraction of a second too late, and it’s useless, or worse, it makes the handling feel weird. Getting that responsiveness right, especially with cobbled-together parts, was incredibly difficult.

What I Learned

Did I end up with a system rivaling a modern luxury car? Nope. Not even close. It was… somewhat active. You could feel it trying, sometimes making things a bit better, sometimes feeling a little unnatural. The biggest takeaway wasn’t a perfectly suspended car, but a deep appreciation for the sheer complexity of real active suspension.

It’s a massive balancing act. Hundreds, maybe thousands of hours of tuning go into factory systems. It’s not just hardware; the software is incredibly sophisticated. Trying to replicate that in a garage? It’s a fun challenge, sure, but you understand why it’s usually found on high-end vehicles. It takes serious engineering resources to get it right.

So yeah, that was my adventure into active suspension. Lots of skinned knuckles, frustrating code errors, and head-scratching moments. Learned a ton, mostly about how much I didn’t know beforehand. Would I do it again? Maybe… but I’d manage my expectations a bit better next time!