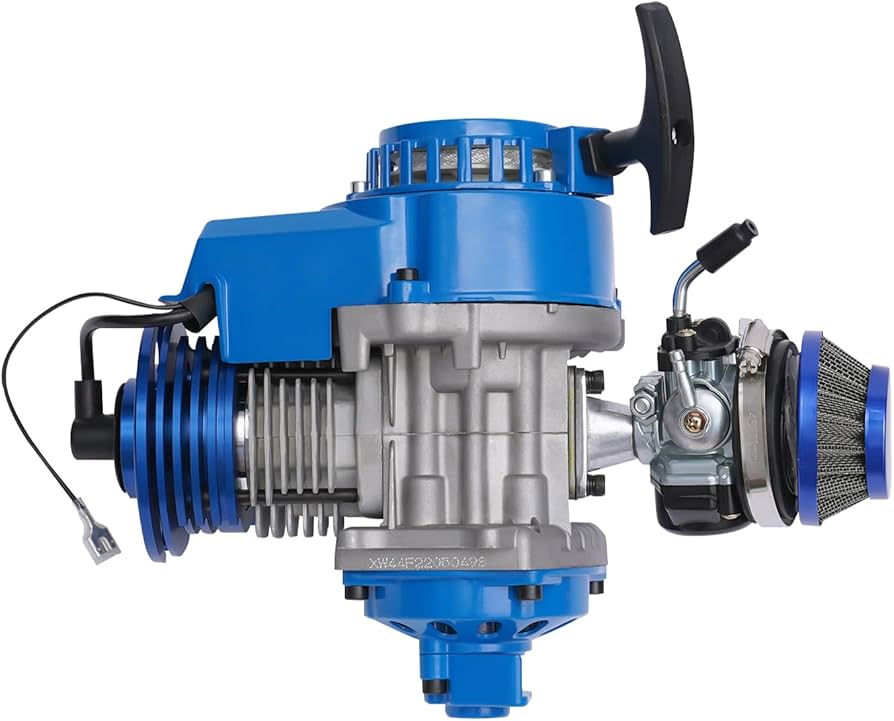

Okay, so I decided to mess around with a 50cc two-stroke engine. I’ve always been kinda curious about these little things – you see them in scooters, some small motorcycles, and even weed whackers. I figured, “Why not take one apart and see how it works?”

First thing I did was find one. I ended up getting a used one off a beat-up old scooter. It was pretty grimy, covered in oil and dirt. That was the first challenge – cleaning it up! I spent a good hour just scrubbing it down with degreaser and an old toothbrush. Gotta see what you’re working with, right?

Once it was reasonably clean, I started taking it apart. I made sure to take pictures at every step. This is super important because, let’s be honest, I knew I’d forget how some of this stuff went back together. I laid all the parts out on a big piece of cardboard, trying to keep them organized. It’s amazing how many bits and pieces are in such a small engine.

Disassembling The Engine

- Cylinder Head: This came off pretty easily, just a few bolts. Inside, I could see the top of the piston and the spark plug hole.

- Cylinder: With the head off, I could slide the cylinder off the piston. This is where the magic happens – the combustion! I noticed the ports on the side of the cylinder – these are for the intake and exhaust.

- Piston: I carefully removed the piston from the connecting rod. It had some rings around it, which I later learned are to seal it against the cylinder walls.

- Crankcase: This is the bottom part of the engine, where the crankshaft spins. Getting into this was a bit trickier, but I eventually got it open. Inside, I saw the crankshaft and the connecting rod.

I spent a good chunk of time just looking at everything, trying to figure out how it all worked. I watched a couple of videos online to get a better understanding of the two-stroke cycle. It’s pretty cool how it does everything in just two strokes of the piston – intake, compression, combustion, and exhaust, all in one go!

Putting it all back together was, as expected, a bit of a puzzle. I relied heavily on those pictures I took. I made a few mistakes along the way – had to backtrack a couple of times. But, eventually, I got it all back in one piece. I tightened everything down, making sure I didn’t over-tighten anything. It’s a good practice for me.

I haven’t actually tried to run the engine yet. That’s the next step! I need to mount it on something and get some fuel and a spark plug hooked up. But just taking it apart and putting it back together was a great learning experience. I definitely have a much better appreciation for these little engines now!